So, today I decided I’d try writing in his fashion, as I’ve always tended to assign human qualities to a great many things that have been a part of my life and talked to them like they were people on many occasions.

The Amerigo, you should already know her name, its Ms. Merry, of course!

Now, Merry’s Chaufer, the trusty old white Dodge pickup, might be a tad more challenging, as his name isn’t really straight forward. His name is Jake, named after his Grandfather, an old red 1979 Chevy C20 Camper Special who drove Ms. Dyna around for my parents when I was a little baby. Jake, however, likes to be called “Red” after his nickname “Redneck Express”, because he thinks it makes him sound tough like a junkyard dog, though he’s more like a sleepy black lab.

Red’s been taking care of Ms. Merry, resting on his back while she undergoes her surgery. Both of them are looking forward to when Ms. Merry is finally done, and its time for Merry, Red, Dawn and Ms. Yuki the Cat to return to the asphalt rivers once again in search of the next horizon.

---------------------------------------------

When we last left off, I was showing you all the new holding tanks for Ms. Merry the Amerigo, who is still feeling rather out of sorts with her insides out and about, scattered into various unsorted piles in the barn with old Mr. Kit, who simply grumbles whenever he’s woke up by me digging around looking for a bit of Ms. Merry to put back and generally mumbles something about “Staying off his lawn”.

Today, I finally decided to tear into Ms. Merry’s floor, the last big mystery left in her bare skeleton.

From the day I first looked at Ms. Merry in her dusty tent up in Washington, I noticed that her floor was rather springy, like walking on a trampoline in some areas. This was very disconcerting, as no Truck Camper’s floor should bounce like a trampoline when you walk on it!

I figured at the time the floor was either built with too thin of plywood when Ms. Merry was put together, or water had gotten into poor Ms. Merry’s floor and the framing had rotted.

So, with all of Ms. Merry’s walls finally put back together and built stronger than ever before, I set about investigating this danged trampoline, as there was no way I was going to put 348 lbs of water on poor Ms. Merry’s floor only to have the tank drop through the first time she decided to climb of Red’s back.

After a great deal of struggle, Mr. Ryobi the Saw and I cut out several peep holes in the floor so I could take a look into Ms. Merry’s floor to find what the trouble was.

The only problem was, every hole I cut, I only found foam!

After a while, Mr. Ryobi the saw was screaming “Enough, this old vinyl and plywood is hard for me to cut, you should using Mr. Milwaukee for this!”, so I got out big Joe and his little buddy Five-Pound, to start ripping up the stubborn plywood and let Mr. Ryobi’s battery go and recharge.

This is what we found:

No rot in the frame! Yay!

Now, there is some water damage to the very thin door skin that covers the bottom, but it appears that’s the only thing affected, and I can replace that later when Ms. Merry’s got all her legs again and she can climb off poor Red’s back and give him a rest.

The plywood also wasn’t rotten, or thin….. like every other plywood piece in Ms. Merry, it was 5/8” plenty thick. So, why was her floor so bouncy?

I didn’t find the whole reason until I spent several more hours with Mr. Ryobi, Big Joe and Five Pound.

Turns out, poor Ms. Merry’s floor wasn’t built very well

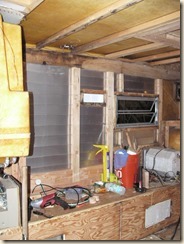

Instead of properly securing Ms. Merry’s floor every so often with cross boards, her floor was simply made up of four 2x2s running length-wise the entire span of the floor with only a couple of very loose 2x4 pieces up towards the front to stiffen it. You can see those in the pictures above.

So, with no solid cross beams, the floor in the middle just bowed up as Ms. Merry’s big rear end sagged down.

Well, we couldn’t have that! So, I asked the two Atwood brothers, “Would you please lift up poor Ms. Merry’s rear end so it straightens back out and I can fix her floor?”

“Sure thing boss! But, you’re going to have to turn us, you haven’t got us any power, yet!” replied the Atwood brothers, who always love a chance to lift something big.

So, out came the crank, and I got myself into quite a sweat spinning down each of the Atwood brothers until Ms. Merry’s rear end had lifted just enough to straighten the floor back out.

Once Ms. Merry’s floor was no longer bent, I got out trusty Mr. Dremel and we cut out the old floor almost all the way back to the rear, removing the bent and twisted floor joists.

After I had finished vaccuuming up the floor and pounding over the staples left from removing the center floor joists, I proceeded to cut new 2x6s to frame up the floor in the front to be strong enough to support Ms. Merry’s new fresh water tank, and then several 2x4s to provide support for the dinette seat compartments where Ms. Merry’s batteries were going to go.

Finally, using a 2x6 and a 2x4, I rejoined the remaining portion of the old floor joists from the rear into the new framing in the front portion of the floor.

My poor arms and Mr. Ryobi the Drill were both fairly sore after driving in all of those large screws to clamp all those new pieces of wood togther so they’d become super strong once the glue set.

We also got to cut our first pieces of insulation

Put down a bunch more glue on the top of all that new wood, then drop in the new sheet of plywood….

Driving in a whole bunch of two-inch screws and the front section of Ms. Merry’s floor is done!

-----------------------------------------------------------------

Well, that takes care of the front portion of the camper, I’ll be able to replace the plywood on the rear section as soon as I remove the toilet from the bathroom so I can move the shower stall out of the way and tear out the last piece of the original plywood.

When they built Merry’s floor, they ran a full eight foot sheet from the rear straight up to the front, then a second shorter piece to complete the run, hence the 2x4s in the photo of the original frame structure. The outer edges of the overhanging section simply have small pieces of plywood added on instead of the rear being cut all from one sheet of plywood.

With the new framing and the same thickness of plywood as the replacement, the new floor doesn’t bounce at all and is quite solid.

Next up, I’ll be finishing the framing on the front wall so I can then insulate and close it up, allowing me to then build the framed box for the new fresh water tank and then i’ll have a step again so I can easily get up to the cabover and finish the floor.

Once the cabover floor is in place, I can really start picking up the pace, first repaneling the ceiling up there, then installing the insulation and new quarter inch plywood to the walls in the cabover.

I’ll be returning to more my regular-style of writing for my following posts, but I’ll probably continue to refer to the camper as Merry and my truck as Red, going forward, however, I think I’ll probably stop giving characterizations to everything else, even if it was kind of fun

Till next time,

Safe Travels