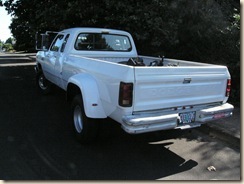

Well, I can officially say that the dually conversion is completed!

In a marathon effort, I drilled, mounted, and wired in the marker lights on the fenders and in the center of the rear of the truck, coated the underside of the fenders and the enclosed sides of the truck bed with Rustoleum Automotive Undercoating Spray, and sanded and painted the ends of the axle tubes where they are visible in the center of the wheels.

So, where to begin…..

Let’s go with the order in which I did them .

Clearance Lights

Perhaps the most tiring part of the job, given that I didn’t wrap it all up till 4am this morning, the marker lights I used are Parker Sealed LED marker light sold for $6.99 each at our local Stuart’s Auto Supply.

Since the D300 the fenders came off of had no marker lights, I had to make the wiring loom from scratch, taping into the feed wires from the tail lights on each respective side of the truck.

I had originally planned to use a wider, more square marker light in my original plans, but changed course when I found the smaller, but similarly illuminated (Each marker light has two bright LEDs in them, in both the ones I used and the ones I had originally planned to use) that had a far more attractive shape and backing plate (Chrome wins over flat black plastic any day of the week ).

I positioned the marker lights on the fenders by first marking the height down from the body crease based on the measurement of the distance between the crease and the front corner marker lights that were already on the truck.

Next, I calculated the change in height along the bottom lip of the fender to figure the distance up from the bottom to get a perfectly level line across the fender and made a mark.

Finally, I traced a using a piece of stiffer cardboard that I could bend to the contour of the fender to trace my positioning line.

The next part involved a little fiddling to see where the light fit best in the curve of the fender and as far out towards the outer edge of the fender as possible while keeping that fit. Once I was satisfied, I marked the drill holes from the base of one of the lights and replicated the placement for the other three marker lights.

Once the drill holes were marked and drilled, I made a larger center hole for the wires to pass through to the underside of the fender where I assembled the wiring loom and secured it inside plastic chaff guard to the underside edge of the fender with cable clamps.

After each fender was wired up, I tested the lights to make sure they functioned correctly before taping and papering off the fender to seal everything up in Rustoleum Automotive Undercoater.

The very last clearance light installed was the three red light bar, which I ended up securing to the lip on the top of the bumper, as there was enough clearance for the tailgate to function properly and saved the hassle of having to cut a notch out of the bumper.

Undercoating the Fenders and Painting the Axle Tube ends

Undercoating was a fairly easy, the most challenging part was laying under the fender and applying the spray without getting rained on by the overspray.

To protect the fiberglass fenders and the side of the truck bed enclosed by the fiberglass fenders, I used Rustoleum Automotive Undercoater.

This product comes in two versions, Regular, which costs around $4 and has a dry time of roughly an hour and “Professional Grade”, which is a little thicker, has a faster drying time, and costs $8 a can.

I used regular, mostly due to cash restraints.

Once the fenders were finished with their wiring and undercoating, I sanded the ends of the axle tube (The section of the hub that you tires go over when you mount them) to remove the mixture of rust and old white paint that was on there, then coated them with gloss black VMF Self-Priming Epoxy Paint.

For the time being, I’ve left the lug nuts alone. I don’t know if cleaning and repainting them will simply cause me problems later on trying to reinstall the lug nuts, or not, so for the time being I’m going to leave them alone.

Conclusion

The dually conversion of my truck has turned as extremely well in the end. There’s still a few minor details to wrap up, caulking the fender gap, installing appropriately redneck dually mud flaps, but all the major details are completed.

Sadly, it’ll be a while before I can really test the truck and camper out to see how it performs with the extra tires in back, so there will likely be a follow up post at some later date detailing how the truck handled.

Thanks to everyone that’s cheered me on and kept up with me during this major undertaking .

Congrats on completing the work! It looks very good to me. Time to go camping and relax! :)

ReplyDeleteErik

Yeah, a little R&R trip would definitely be welcome, just haven't solved the gas money issue yet. :p

ReplyDeleteHopefully, I'll be back to work soon, and I can compile my funds to head back to Illinois next year.

Illinois? Not before the Fall Colors Run...LOL!

ReplyDeleteGreat Job! Cheers! ~M

If you stop in IL let me know where so we can meet up ok?

ReplyDeleteErik

Well, so far it looks like the trip next year is back on, it'll be in September, just after the labor day weekend.

ReplyDeleteIf all goes well, I'll be heading down towards Kankakee where my family is at to visit, but I will be up in the Chicago area more than once, at least twice when Dawn flies out to O'Hare to join me for a couple weeks.